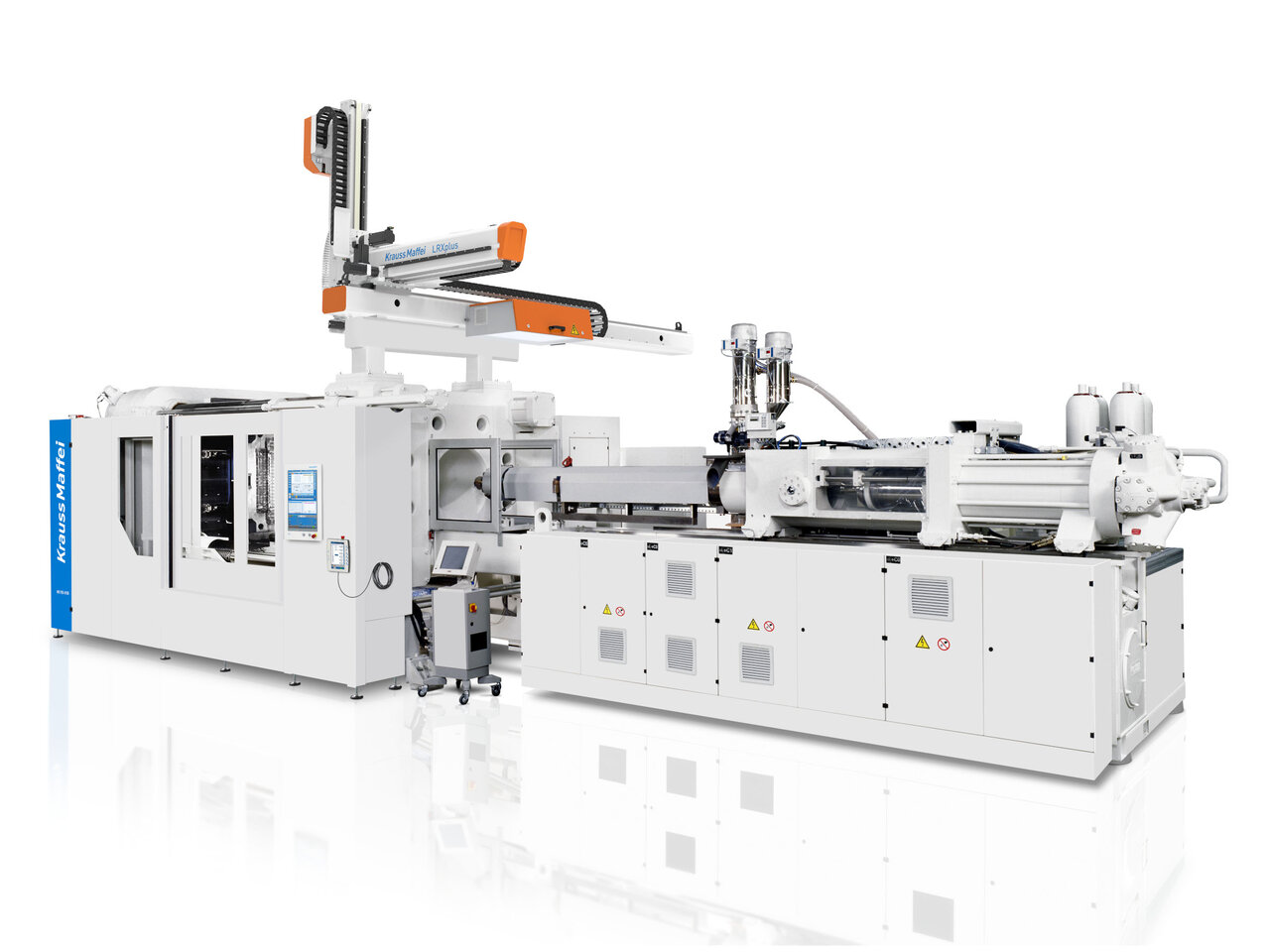

Chopped Fiber Processing (CFP)

Unique processing of cut glass - simple material cost savings

Product information

In the chopped fiber processing (CFP), chopped fibers (e.g. glass fibers) are added to the pellets at the infeed of a plasticizing unit via an additional metering system and processed gently using a new special KraussMaffei screw geometry. This processing concept enables fiber-reinforced components to be produced cost-effectively with very good properties.

- Manufacture of high-quality, fiber-reinforced components with customized property profiles

- Significant reduction in material costs, ROI < 1 year

- Compatible and retrofittable on standard injection molding machines