Comet and Hybrid

The filler professional and the Modular design, flexible configuration

Product information

The Comet and Hybrid metering machine series from KraussMaffei offer two high-performance solutions that impress with constant process parameters, modern control technology and high adaptability. Both systems are the perfect technology for processing fillers premixed in polyol and/or isocyanate, such as short glass fibres, melamine, barium sulphate, expandable graphite or similar, to produce components with high strength or special flame-retardant properties. While Comet relies on servo-hydraulically controlled pistons, the Hybrid series combines piston and pump technology for maximum flexibility.

Use cases

Industries

Automotive

Medical technology

Public Transportation & Utility

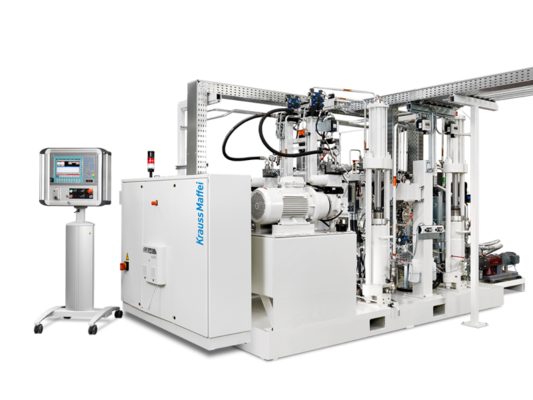

Comet

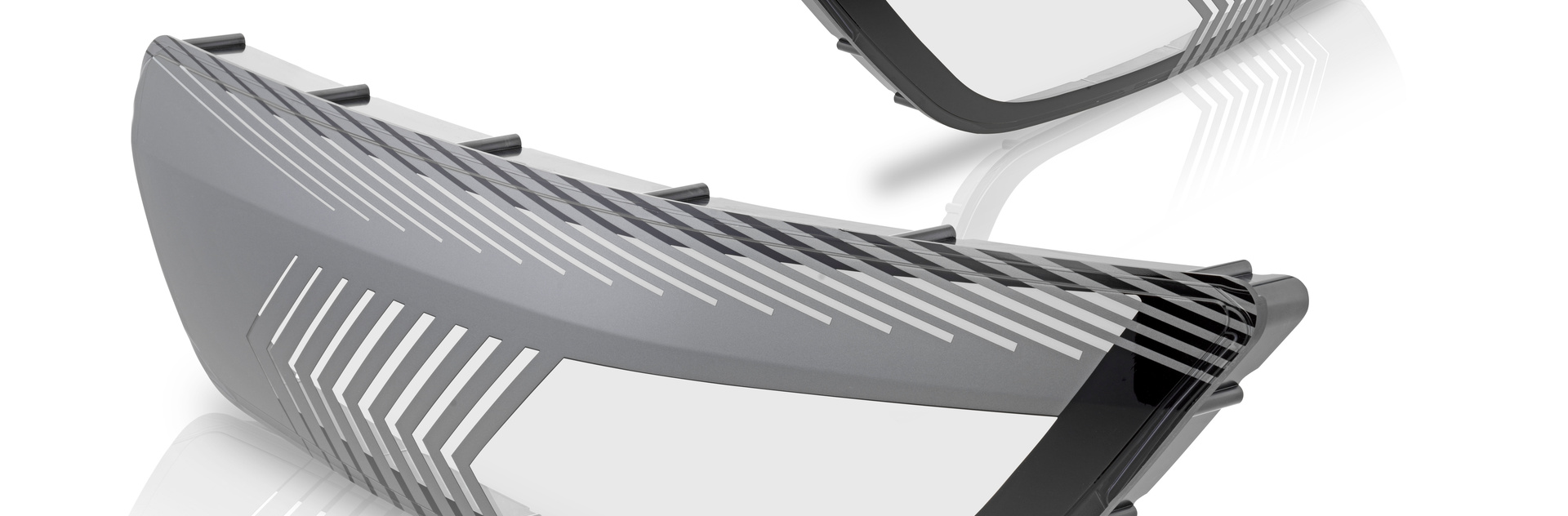

The Comet series is suitable for a wide variety of filler components in the automotive industry: the Comet can be used in many different ways for front panelling, side skirts or wings.

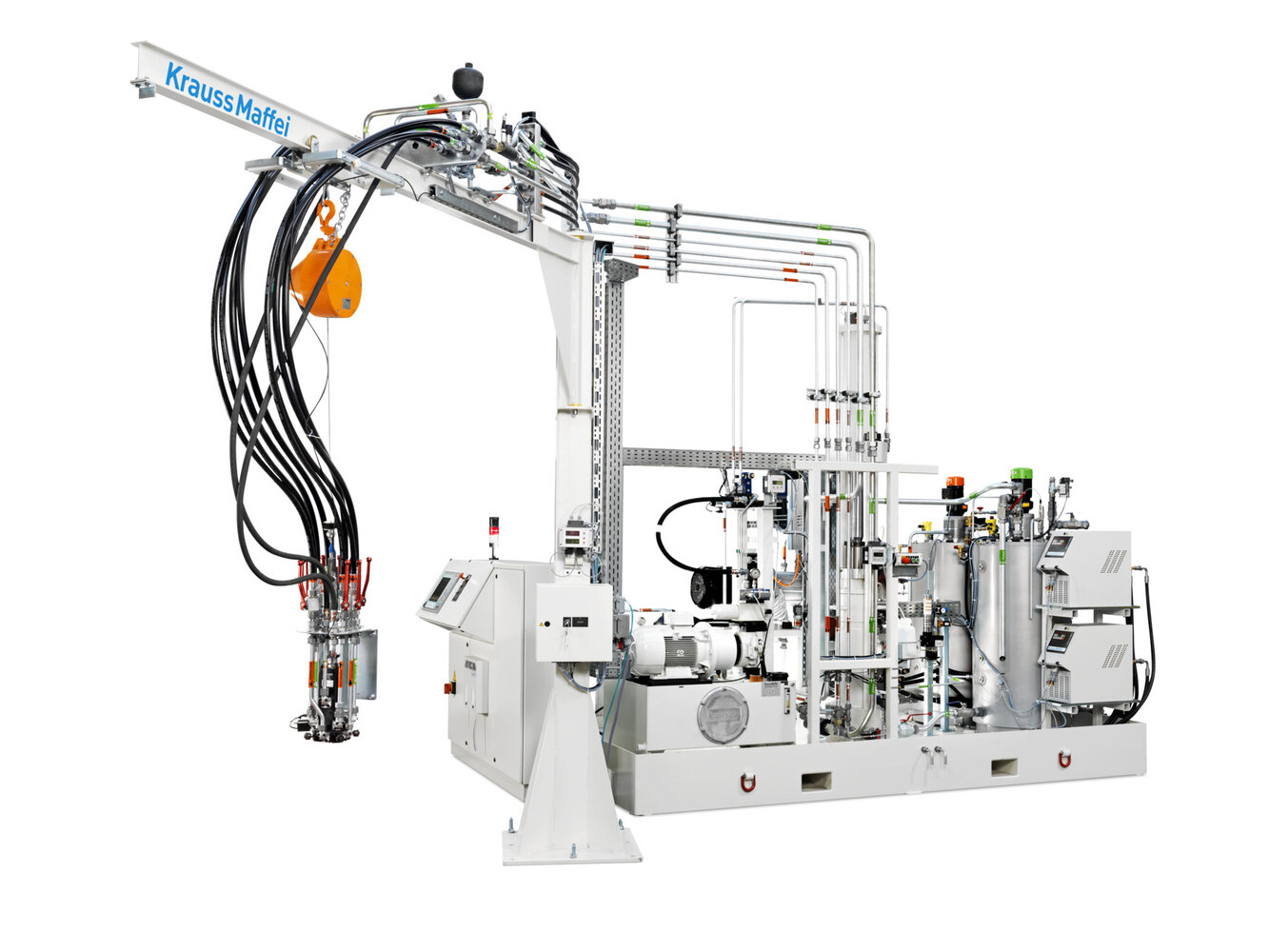

Hybrid

The Hybrid series is suitable for a wide variety of filler components in the automotive industry: the Hybrid can be used in a variety of ways for front panels, side skirts, fenders or insulation components. It is also ideal for seats filled with expanded graphite in aeroplanes or trains.

Medizin - Gehäuse

Multi-part housing, structural rigid foam, painted surface |

Transport - Hybrid

The Hybrid series is suitable for a wide variety of filler components in the automotive industry: the Hybrid can be used in a variety of ways for front panels, side skirts, fenders or insulation components. It is also ideal for seats filled with expanded graphite in aeroplanes or trains.

Nutzfahrzeuge - Comet

The Comet is ideal for manufacturing trim parts in the commercial vehicle sector. It is also suitable for manufacturing wheel covers and for many other R-RIM applications.

Metering Technology for the Highest Demands – Comet & Hybrid

The piston machine for demanding PUR formulations, operable both hydraulically and electrically. The Comet series from KraussMaffei is specifically designed for processing PUR systems with abrasive fillers. It stands out for its high flexibility, precise control technology, and consistent process parameters – even with challenging materials and applications.

Key Features – Comet Metering System

- Consistent process parameters, even with filled PUR systems

- Servo-hydraulic drive for high metering accuracy

- Proven tank concept for reliable material supply

- Especially suitable for applications with high demands on temperature and fillers

Combination of Pump and Piston Metering - Pump metering for isocyanate and piston metering for polyol.

The Hybrid metering machine is designed for processing standard isocyanates and filled polyols. Thanks to its modular design, it can be individually configured and adapted to specific customer requirements.

Key Features – Hybrid Metering System

- Consistent process parameters, even with filled systems

- Outstanding part quality through precise control technology

- Maximum production and process reliability

- Accurate delivery rates and shot weights