IMC Technology

Injection Molding Compounder - Clever Compounding integration

Product information

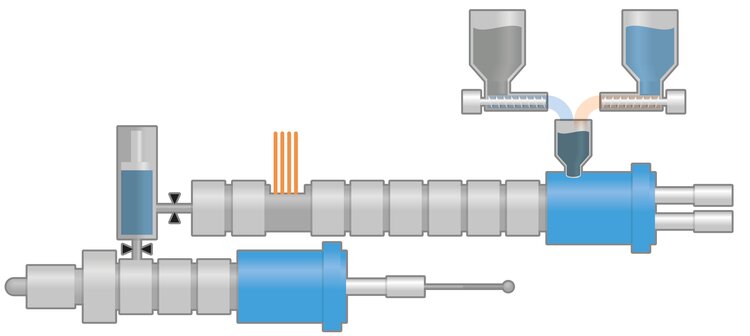

The Injection Molding Compounder (IMC) combines the continuous compounding process from extrusion technology with the discontinuous process of injection molding. It therefore enables inline compounding in the injection molding process for almost all compounds and offers a high material cost-saving potential. The extruder has a modular design and is configured to suit the specific application. To decouple the continuous compounding process from the discontinuous injection molding process, a material accumulator is used to temporarily store the melt supplied by the extruder during the injection and holding pressure phase. In the transfer phase, this melt is then transferred to the so-called shot pot at the same time as fresh melt from the extruder. A transfer valve is used to separate the high-pressure area of the shot pot from the low-pressure area of the extruder during the injection and holding pressure phase.