Premixing station - solids metering

Efficient preconditioning for PU systems with fillers

Product information

Our premixing stations enable fully automated preparation of PU components with abrasive solids such as glass fibers, barite, or melamine. Also suitable for shear-sensitive solids such as expandable graphite. The modular systems are designed for seamless integration into existing production environments and ensure consistent quality and process reliability.

- PU molded parts with solid fillers

- Insulation materials and technical components

- Applications requiring high mixing quality and process stability

- Modular design for customer-specific configurations

Advantages that make the difference.

High mixing quality

through controlled dosing and agitation

Automated supply

of the metering machine’s day tank

Flexible integration

into existing production lines

Use cases

Industries

Sprühmischkopf

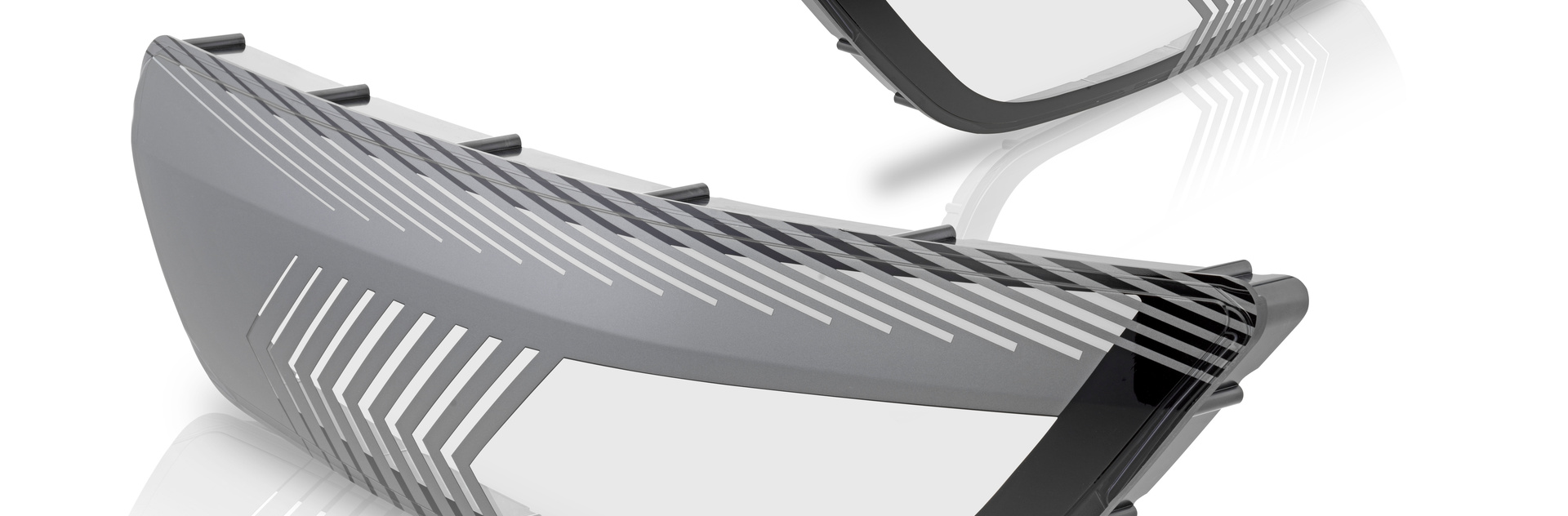

Comet

The Comet series is suitable for a wide variety of filler components in the automotive industry: the Comet can be used in many different ways for front panelling, side skirts or wings.

Hybrid

The Hybrid series is suitable for a wide variety of filler components in the automotive industry: the Hybrid can be used in a variety of ways for front panels, side skirts, fenders or insulation components. It is also ideal for seats filled with expanded graphite in aeroplanes or trains.

NVH - Bauteile

For the manufacture of components in the automotive sector that serve to dampen sound and vibration as well as provide thermal insulation.

Automobil-, Motorrad-, Möbelsitz

Oval systems are largely used for the series production of seat cushions and backrests for automotive production. The large number of foam seat parts per vehicle and the wide range of variants from comfort to sports seats require systems with maximum flexibility and very high part output.