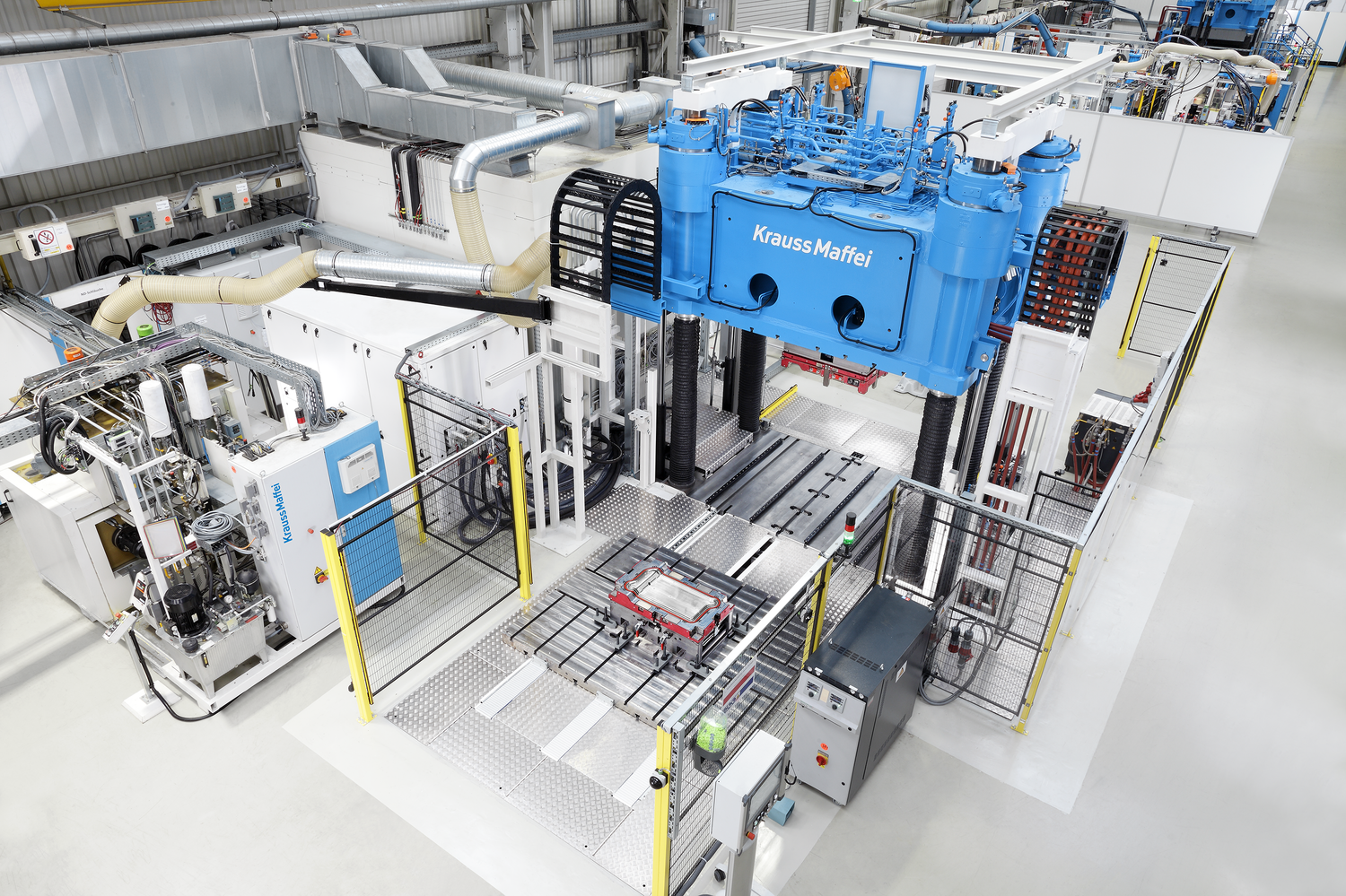

SFT-MX mold carrier

High speeds for low cycle times

Product information

The new SFT-MX model mold carriers with a clamping force of up to 10000kN is characterized by its low overall height. At a total height of just 5.2 m, it can even be installed in plants with low ceilings.

Depending on process requirement, the MX series can be carried out for the most precise parallelism control via all columns with a force-travel-controlled compression function.

It is also extremely easy to maintain. All hydraulic cylinders can be accessed quickly and easily, most of the hydraulic components are placed at ground level and wear parts have been reduced to a minimum.

Both mold fixing platens are freely accessible so that molds can be changed from the back as well as the front.

- Compact design with low overall height

- Highest precision as a result of the optional parallelism control

- Ease of maintenance thanks to a reduction of wear parts and good accessibility

Advantages that make the difference.

Up to 10000kN

of clamping force

Just 5.2 m

of total height

Wear parts

have been reduced to a minimum

Use cases

Industries

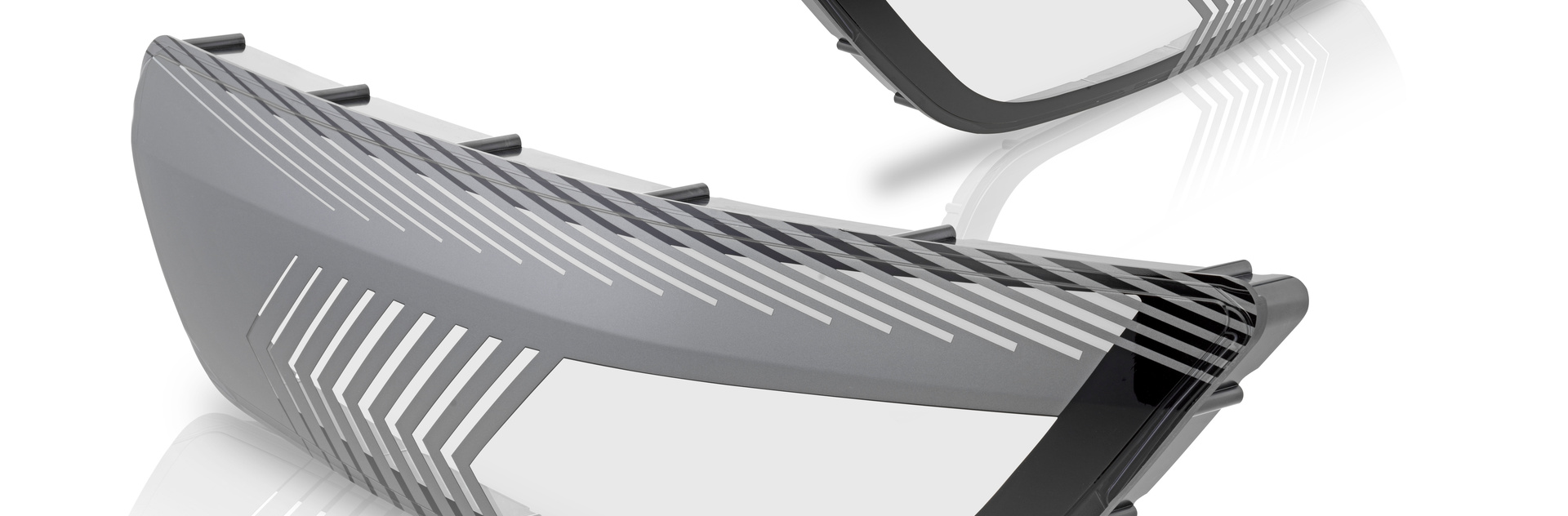

LFI Frontpanel

PU component with 25 % long fibre reinforcement, manufactured using the LFI process with thermoformed decorative film; fibre length and volume content adapted locally, further refinement by painting with barrier coating.

Nutzfahrzeug Dachelement

PU component with long fibre reinforcement, manufactured using the LFI process with in-mould painting for the visible side.

LFI-Schäumwerkzeug Motorhaube

HP-RTM