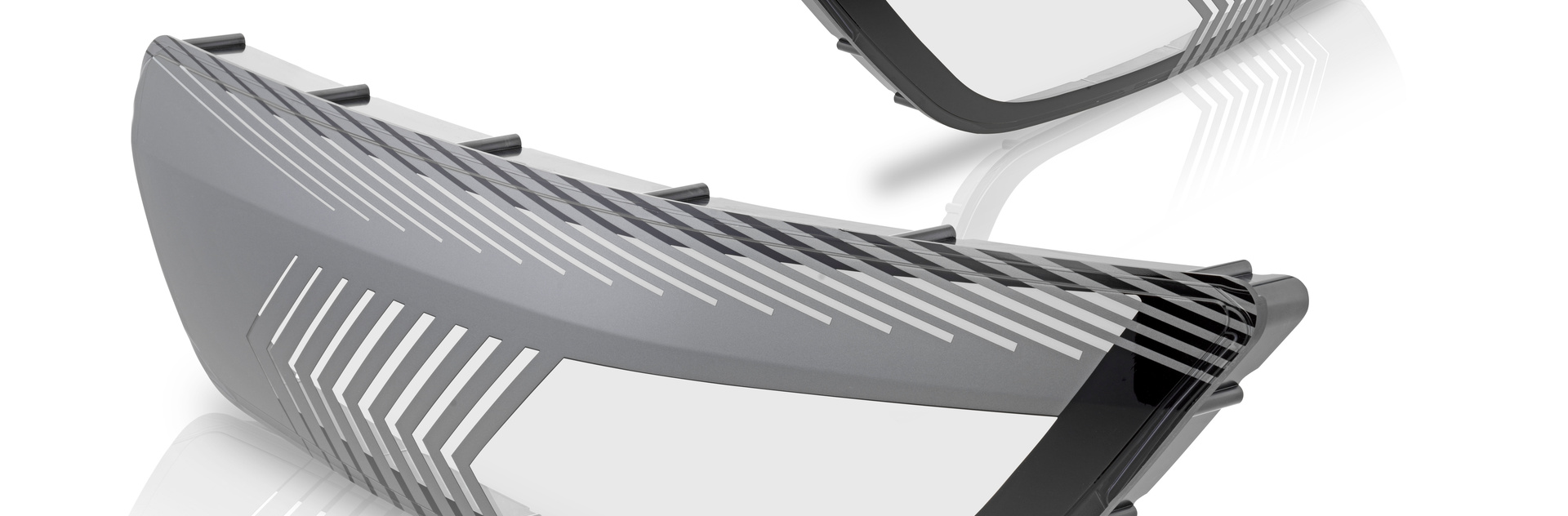

Steering wheel mold carrier

Precision, stability, and process reliability for steering wheel production

Product information

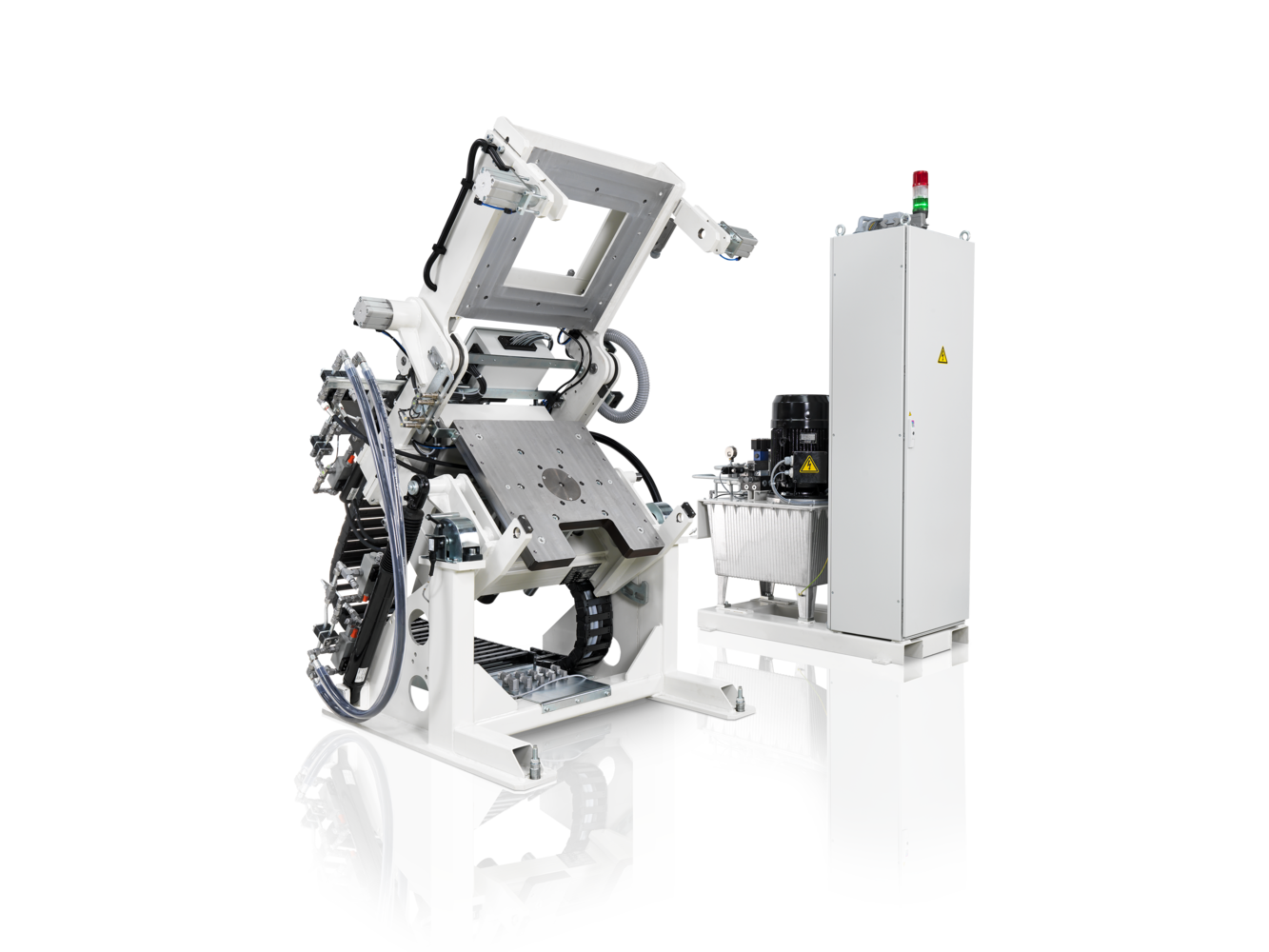

KraussMaffei’s Steering Wheel Mold Carrier is a high-performance solution for the production of PU-foamed steering wheels. Designed for maximum flexibility and automation, it ensures consistent quality, fast cycle times, and seamless integration into modern production environments.

- Independent hydraulic unit per mold carrier – no interference between stations

- Proportional hydraulics – adjustable tilting from 0° to 90°

- Pneumatic safety locks – for both lid and frame

- Reinforced lower platen – for optimized tool sealing

- Full side access – ideal for robotic applications

- Modular design – easy to expand with additional MC units

Advantages that make the difference.

600 × 600 mm

Platen size

100 kN

Clamping force

275 mm

Max. opening daylight

Use cases

Industries

Automotive

Automotive

Lenkrad

Steering wheel production is based on stationary moulding systems and includes mould carriers, dosing technology with paint dosing, painting technology, handling and extraction technology – also for explosion-proof applications.