Presses

Scalable solutions

Product information

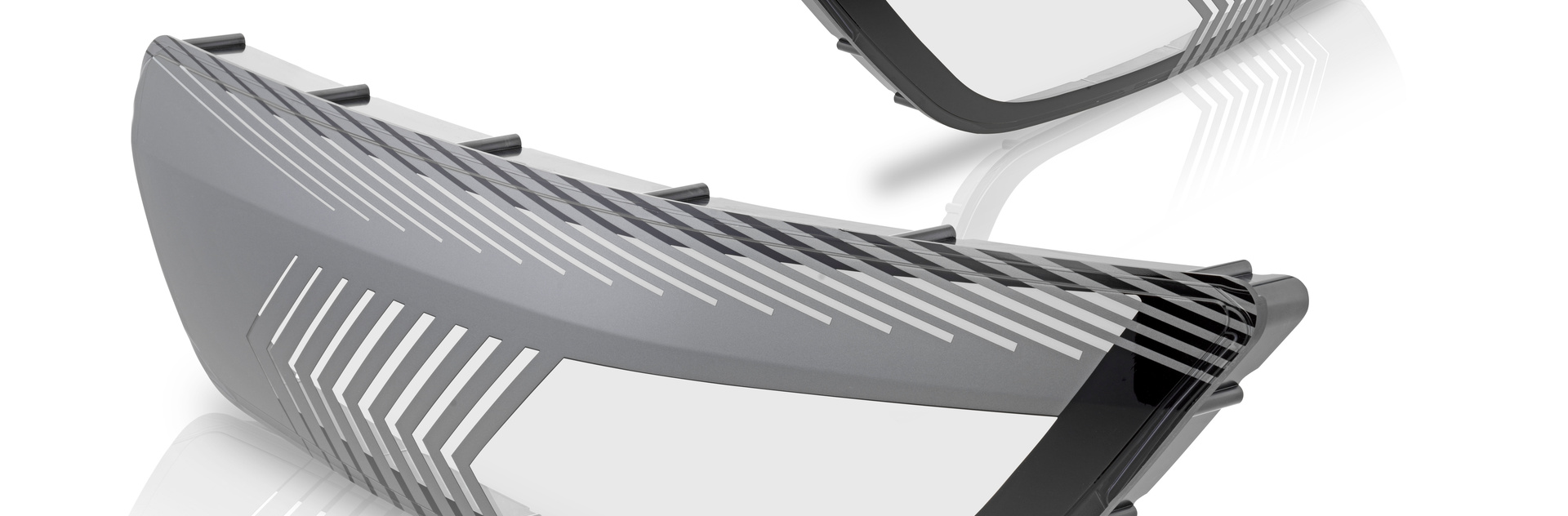

Our press technology stands for modular and scalable solutions - from single presses to highly automated 1+1 or 2+2 shuttle systems for maximum efficiency. The systems are specially designed for large formats. Thanks to their high flexibility, different materials, panel thicknesses and moulding concepts can be easily integrated. Depending on requirements, the presses can be equipped with automatic loading and unloading, side limiters or mixing head carriers. Precise temperature control, high repeat accuracy and Industry 4.0 capability ensure maximum process reliability and future viability.

Use cases

Industries

Cooling Technology & Insulation

Infrastructure & Construction

Kühllastwagen - Isolation

Suitable for insulated and chilled or temperature-controlled transport of foodstuffs.

Kühlräume - Isolation

Suitable for insulated and refrigerated or temperature-controlled storage of food or other goods.

Kühlcontainer - Isolation

Suitable for insulated and refrigerated or temperature-controlled transport of food or other goods.

Fertighäuser - Isolation

Sandwich elements based on OSB or mineral boards and polyurethane foam cores are sometimes used in the manufacture of prefabricated houses.

Solarpaneele - Isolation

Our product forms the basis for mirrors in solar thermal power plants – precisely shaped and perfectly insulated.

Presses

1+1 press concept: Two movable press plates work alternately – while one plate foams and cures, the other is already being prepared or unloaded

→ Virtually no downtime

2+2 press concept: Two parallel 1+1 systems – ideal for doubling production capacity with high volumes

- Open or closed mold foaming possible

- Suitable for all blowing agents, including pentane

- Wide range of materials: Wood, metal, OSB, concrete, gypsum board

- Compact solution despite large-format production