Special Mixing heads

The right mixing head for every special application

Product information

Whether spraying, flooding, fiber reinforcement, or precise dosing: our mixing heads cover a wide range of PUR processes and offer the right technology for every challenge. From high-precision high-pressure mixing heads to flexible low-pressure solutions, all systems stand for excellent mixing quality, reliable process control, and maximum design freedom for your production.

Use cases

Industries

Automotive

Infrastructure & Construction

Consumer Goods

LFI Frontpanel

PU component with 25 % long fibre reinforcement, manufactured using the LFI process with thermoformed decorative film; fibre length and volume content adapted locally, further refinement by painting with barrier coating.

Nutzfahrzeug Dachelement

PU component with long fibre reinforcement, manufactured using the LFI process with in-mould painting for the visible side.

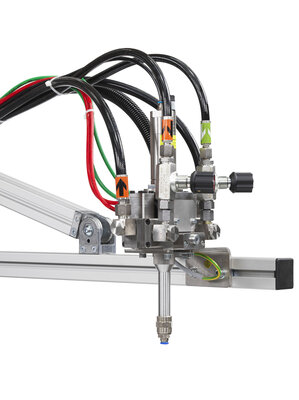

Sprühmischkopf

Instrumententafel - Hinterschäumen

Injection moulded carriers, PUR and decorative surfaces are reliably bonded together.

ColorForm-Interior bars

ColorForm component with integrated functions: In modern electric cars, touch sensors for controlling functions are integrated into components with a ColorForm surface. The integrated production of the carriers and surfaces in a single step is also particularly efficient and sustainable.

HP-RTM

CCM-Bauteil

In the automated CCM (Clear Coat Molding) process, high-quality components are flooded with a transparent two-component PUR system.

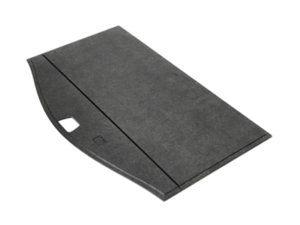

Bodenmatte - Sprühmischkopf

The armoured spray mixing head is suitable, for example, for processing with abrasive BaS04 (barite) for sound absorption, for example for front wall insulation, carpets or floor mats.

Sieb - Bergbau

PUR screens for the mining industry impress with their low wear and long service life for classifying rock.

Schneewalze

At the end of the preparation process, PUR smoothing boards on the snow groomer smooth the snow and create fine grooves for perfect slope quality.

A solution for every application

Our spray mixing heads have been specially developed for the requirements of a wide range of spray technologies – with the aim of offering you maximum flexibility and creative freedom in design. Whether complex geometries, fine surfaces or large-area applications: the technology behind our spray mixing heads ensures uniform, precise distribution of the material, enabling high-quality results in every application.

Core features of the spray mixing head

- Armored mixing head for highly filled PUR systems

- Excellent mixing quality even with extreme mixing ratios

- Low overspray, sharp spray boundaries

- Material savings through optimal material application

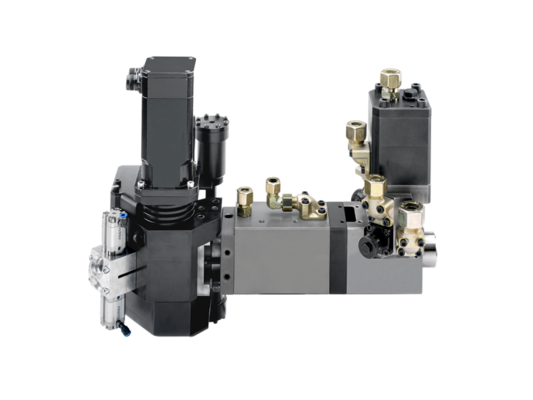

In the automated CCM (Clear Coat Molding) process, high-quality components are flooded with a transparent two-component PUR system. The CCM mixing heads ensure optimum temperature control of the raw materials. Even small discharge quantities are perfectly mixed and fed into the cavity without bubbles.

In a ColorForm application, coloured PUR or PUA coatings are applied in a closed mould.

Key features of the ColorForm CCM mixing head

- Filling process with perfect mixing for optimum component quality

- High reliability and durability

- High flexibility in nozzle technology

- Self-cleaning, maintenance-friendly design

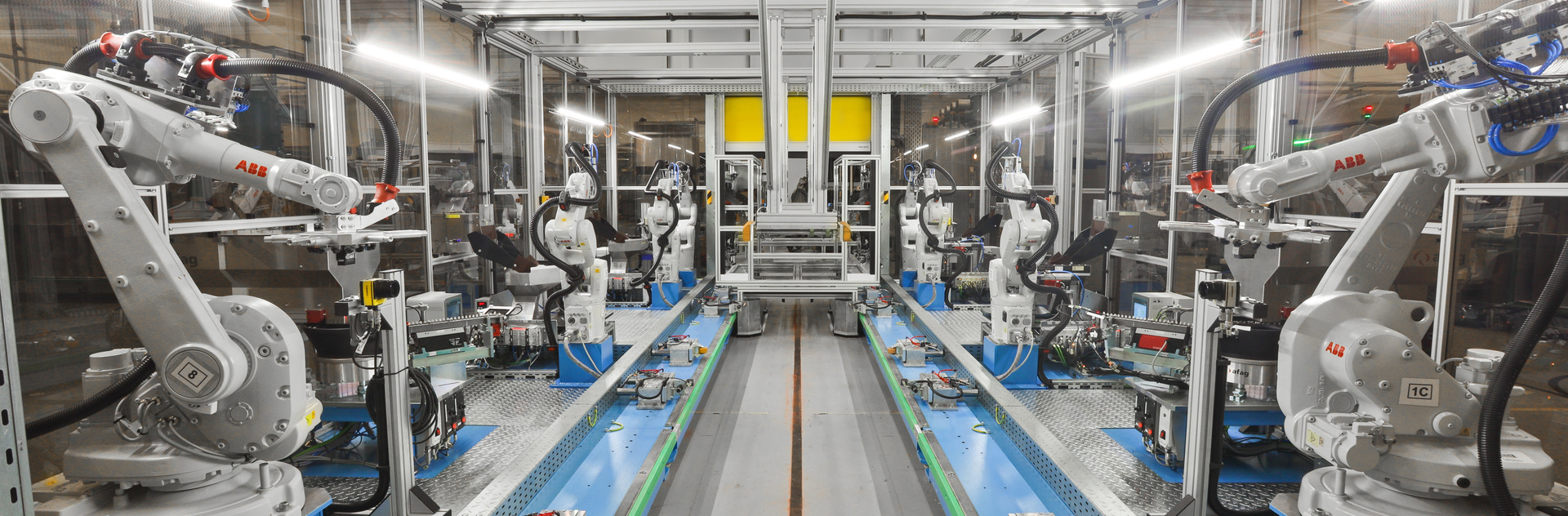

The LFI-PUR Long Fiber Injection Polyurethane process is used to manufacture high-strength lightweight components. The LFI process unit has three essential tasks that are crucial for the quality of the end products:

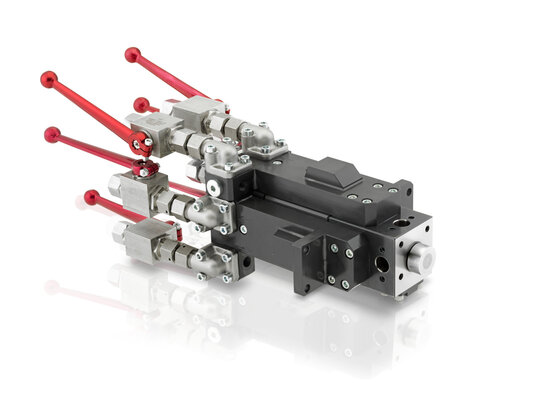

Core properties of long fiber injection (LFI) Mixing head

- Conveying and cutting the roving

- Mixing the reaction components

- Wetting the reinforcing fibers with the reactive mixture

- Adjusting the fiber quantity and length as required

- Flow-optimized geometry of the cleaning piston

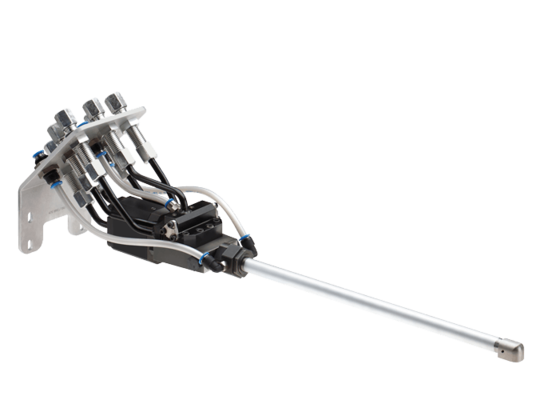

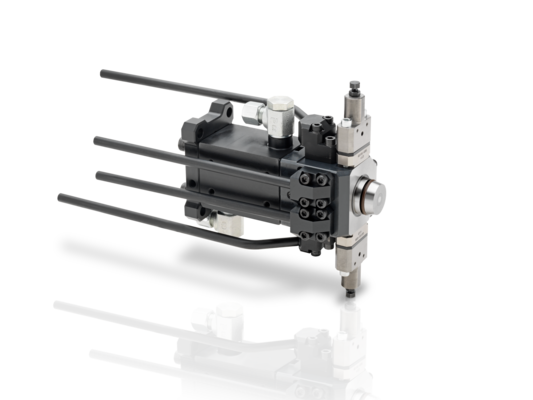

This compact and highly efficient linear mixing head is suitable for processing fast resin systems in the HP-RTM process with high-pressure mixing for the production of lightweight and high-strength components.

Core features of the resin transfer molding RTM mixing head

- High degree of process reliability and repeatability

- Production of high-strength components in large quantities

- Production of excellent surfaces

- Can be used at high mold temperatures

High-pressure deflection mixing head with 2 separate mixing chambers and one outlet pipe.

Our low-pressure mixing head offers an economical solution for applications with small shot quantities and low investment requirements. Mixing is carried out by a rotating agitator at pressures below 10 bar – ideal for difficult-to-mix systems and precise dosing from 0.5 g/s.

Particularly suitable for niche processes where flexibility and simple system technology are paramount.

Key features of the low-pressure mixing head

- Easy option to run 2 different components one after the other

- Quick change between 2 systems in one system

- Easy control and integration into existing systems

- All the advantages of our deflection mixing heads