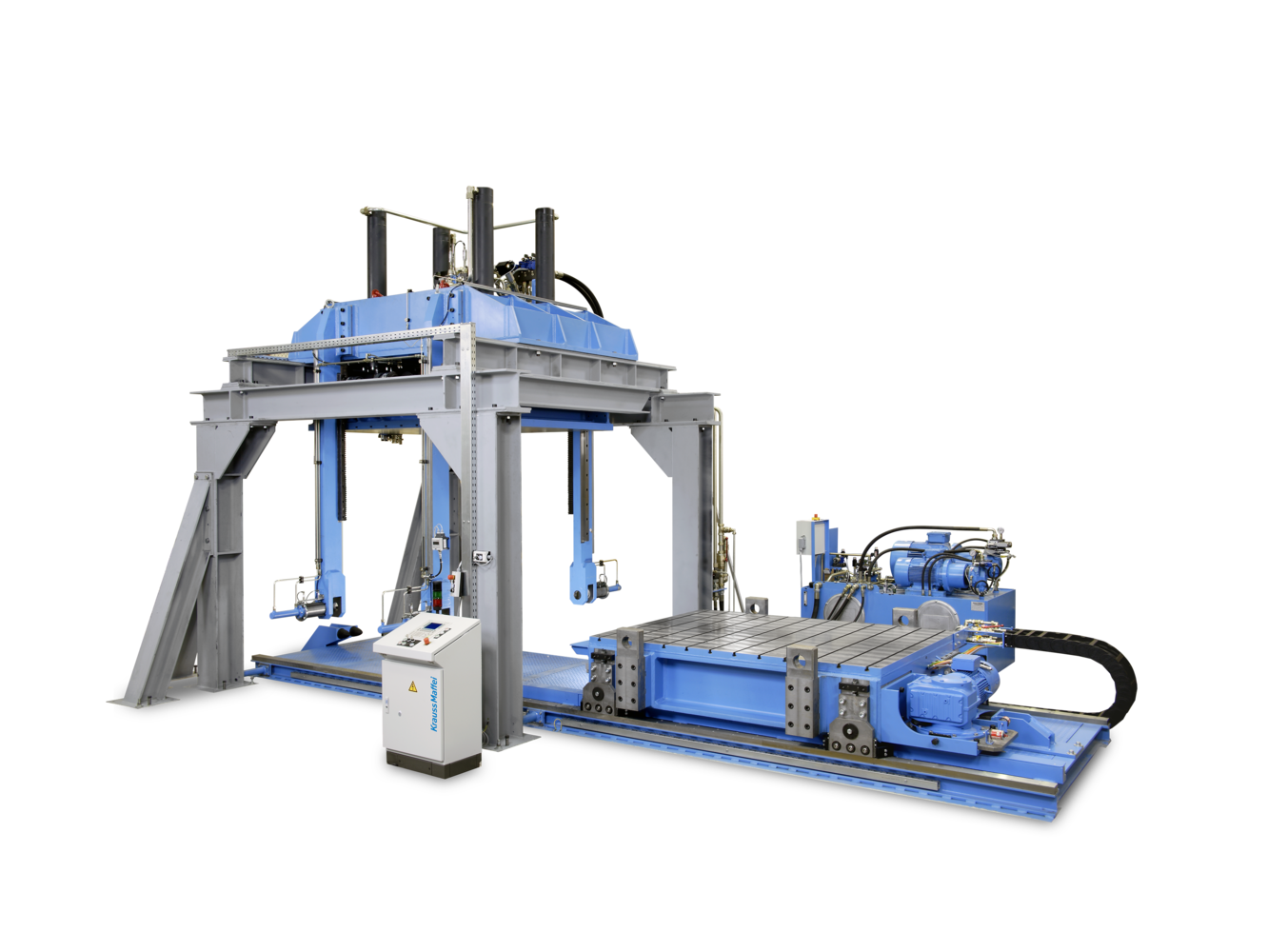

Shuttle mold carriers

For long-fiber injection processes for manufacturing large area components

Product information

The shuttle carriages are use to quickly transport the bottom mold between various bottom mold processing stations and is driven using a servomotor. As a result, the foam discharge, for example, can occur in the bottom mold outside of the clamping unit.

The upper mold fixing platen parallel stroke is guided by the integrated guide frames.

Another distinguishing feature of the series is the tilting movement of the upper and lower mold fixing platens.

Thanks to their high degree of stiffness and positioning accuracy, Shuttle mold carriers are suitable for positive molds, LFI molds and molds that are not inherently rigid.

- Use during large-format component manufacturing processes

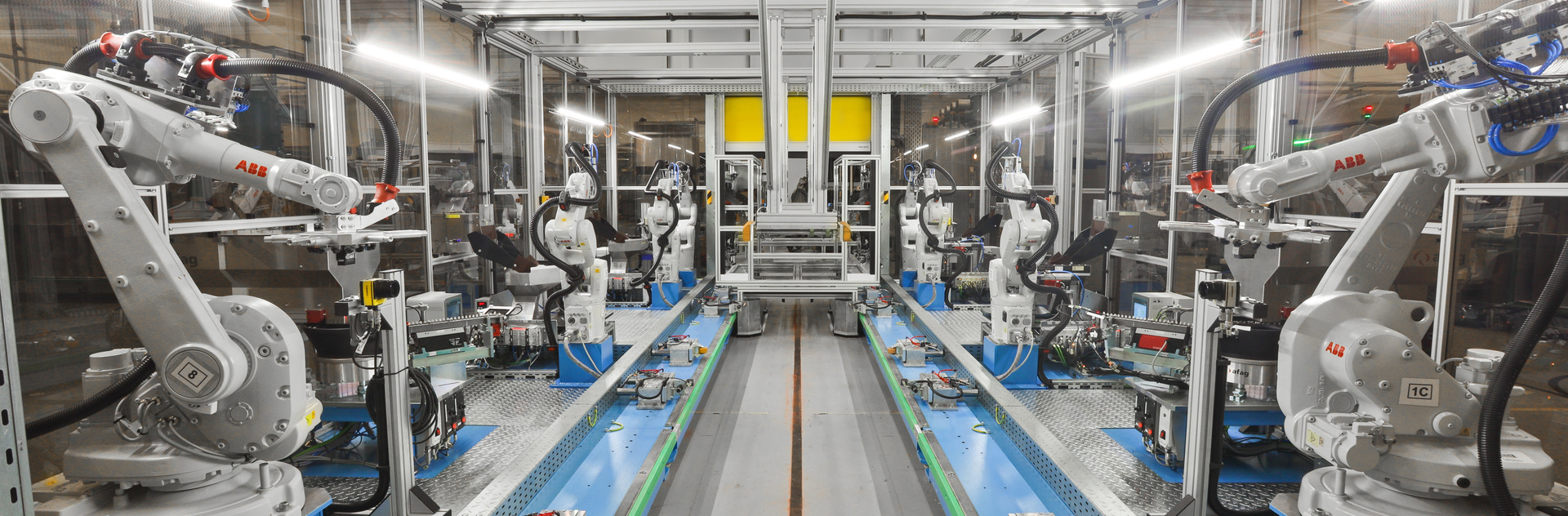

- Optimal freedom of movement for mold pouring robots

- Ground-level structure without pits or foundations

- Low overall height and ground-level operation for best ergonomics

Use cases

Industries

Automotive

Nutzfahrzeug Dachelement

PU component with long fibre reinforcement, manufactured using the LFI process with in-mould painting for the visible side.

LFI Frontpanel

PU component with 25 % long fibre reinforcement, manufactured using the LFI process with thermoformed decorative film; fibre length and volume content adapted locally, further refinement by painting with barrier coating.