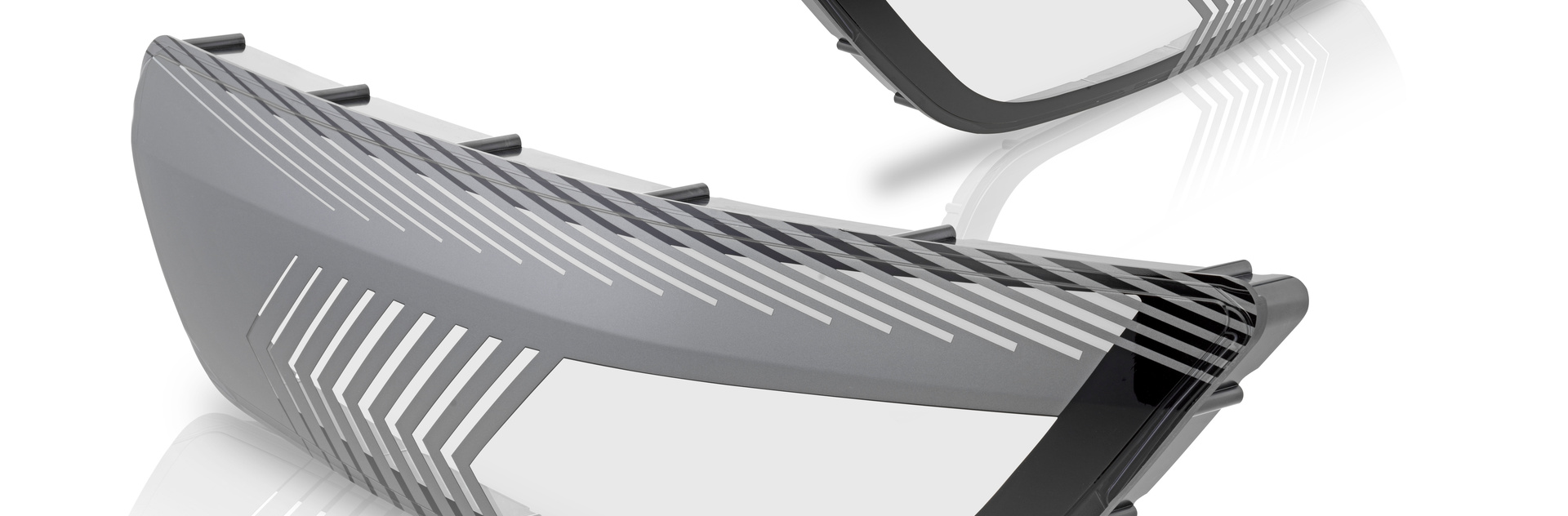

Punching Tool

Precision at micrometre level

Product information

Our sophisticated tool architecture combines precisely matched punching knives, dies and guide elements - for perfect cuts with every stroke. Integrated sensor technology enables seamless process monitoring. Segmented dies with intelligent part recognition ensure maximum production reliability and minimise rejects.

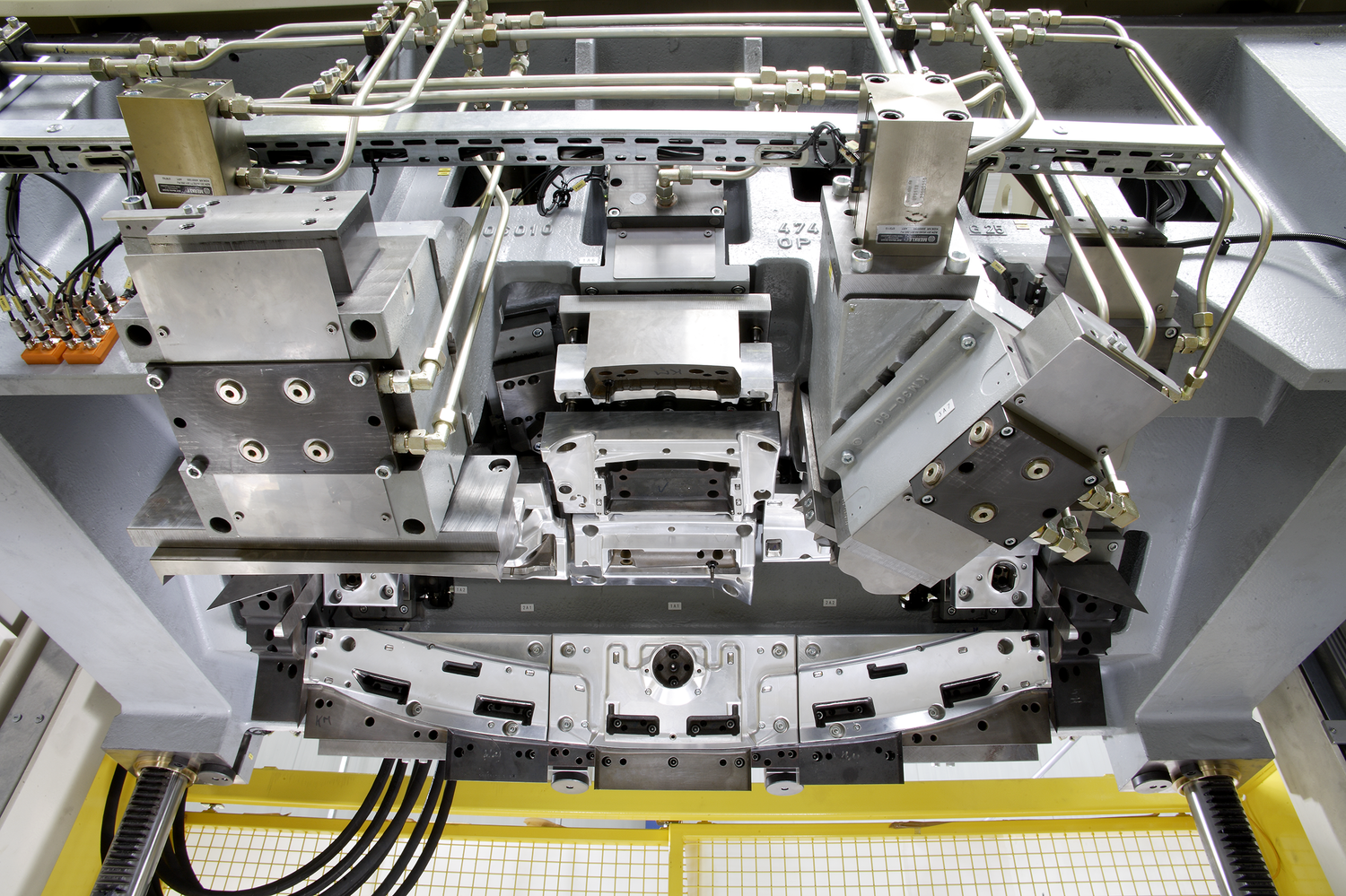

Thanks to seamless automation and full compatibility with automated lines - including robot handling and innovative tool change concepts - the punching tool is ready for the future of your production 4.0.

- Hydraulically guided slider units for high-dynamic punching operations

- Integrated or separate tooling concepts – adaptable to various machine types

- Product receiver with part lifters ensures smooth handoffs in automation

- Modular upper and lower tool design – service-friendly and efficient

Use cases

Industries

Cooling Technology & Insulation

Türmodul

Instrumententafel - Hinterschäumen

Injection moulded carriers, PUR and decorative surfaces are reliably bonded together.

Kaschierte innenraum Bauteile

The backing is firmly bonded to the skin using an innovative thermal bonding technique with a PUR core layer. The skin envelops the backing and can be flexibly guided around corners – for perfect adaptation to different geometries.

Haushaltskühlschränke - Isolation

Polyurethane is the ideal material for achieving first-class energy efficiency.